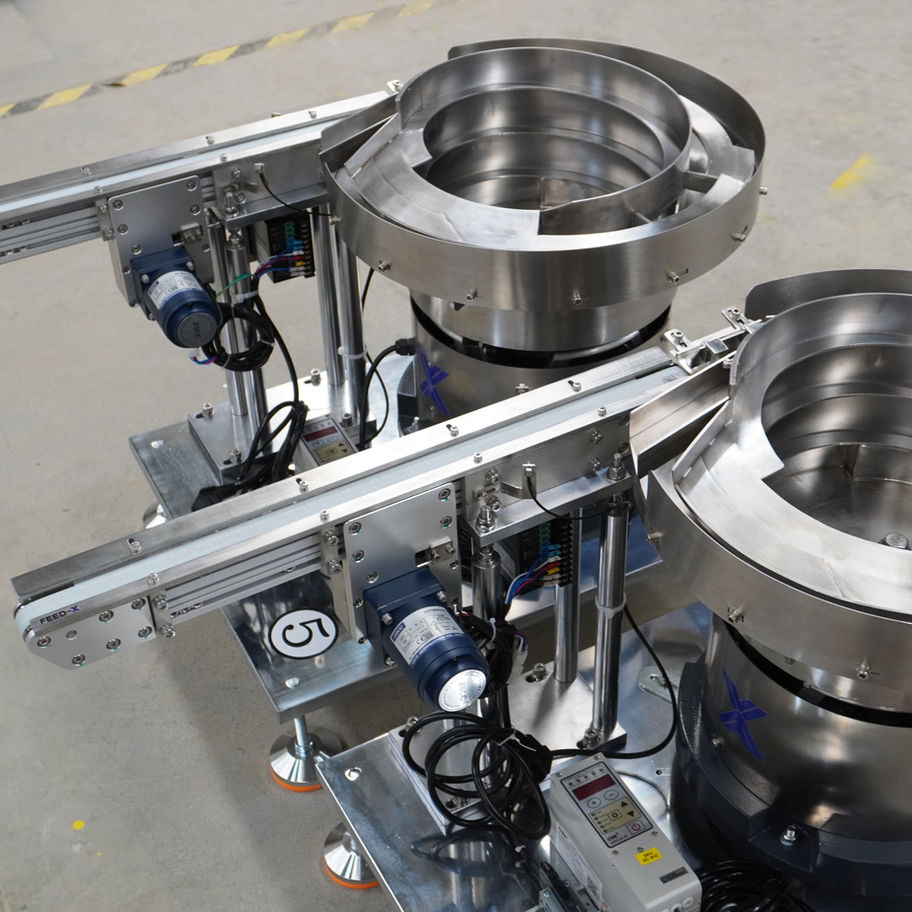

Bowl Feeder

A bowl feeder is an automated part feeding solution designed to orient, separate, and deliver small components using controlled vibration. It ensures a stable and continuous flow of parts into assembly, inspection, or packaging operations, making it ideal for high-precision and high-repeatability manufacturing environments.

This solution is particularly well suited for small or complex parts and is commonly used in robotic cells and manual workstations across industrial facilities in California, U.S.

Technical Specifications

- Fully custom-engineered design: Each bowl feeder is designed specifically around your part geometry, target cycle time, and production volume.

- Process-focused engineering: Our engineering team evaluates your application to develop a reliable feeding solution that maximizes uptime, consistency, and operational efficiency.

Delivery & Lead Time

- Turnkey delivery: The system is delivered fully configured and ready for operation, requiring no additional tuning.

- Lead time: 8–9 weeks after final design approval.

- Technical assistance available: Support is available during installation and startup upon request.

Pricing & Quotation

Because each feeding system is custom built, pricing depends on the technical requirements of the application, part complexity, and feeder design.

Contact our engineering team to request a tailored quotation aligned with your production requirements.

Soluciones para la industria

.png)

Médica y farmaceutica

.png)

Automotriz

.png)

Electrónica

.png)

Alimentos y Bebidas

.png)